-

For smoothing all types of surfaces

Continuing to meet the challenge of producing abrasives regardless of size or shape for plastics, metals, and ceramics.

-

The science of abrasives

Abrasive techonologies are old, but constantly changing. We strive to generate new technologies based on fundamental principles that depart from experience and intuition and do away with excesses, irregularities, and waste.

-

The best solutions for surface processing

Optimal surface processing cannot be achieved only with materials. We concentrate on the know-how acquired over many years to solve problems together with our customers.

Making history and connecting with the future

The ancient people of the stone ages relied on “polishing technologies” to transform stones and bones into useful tools. This amazing techonology evolved with human civilzation and has developed into the abrasive materials used today. Natural minerals were at one time used for artificial abrasives, but today, fused alumina and silicon carbide are the mainstream materials. After World War II, Fujimi focused on the future of man-made abrasives and succeeded in making the first abrasives in Japan. In the 60 years that followed, Fujimi has been involved in “cutting”, “machining”, “grinding”, “lapping” and “polishing” and has provided high precision abrasives to customers around the world.

Fujimi's abrasives are now used in a range of high-precision activities for manufacturing electronic components (such as semiconductors, hard disks, and crystals) LED lighting, solar cells, automobiles, cameras, and eyeglass lenses. When transistor radios first appeared and were rapidly sold around the world, Fujimi abrasives were used to make the semiconductors that went into this product. Since that time, abrasives have been created to meet the highly precise and ultra-pure environment needed to produce highly integrated semiconductors. Fujimi's abrasive technologies are used on the sapphire substrate for LED lighting, which is exceptionally hard and difficult to process. Our abrasives are also used to polish lenses for single lens reflex cameras to eliminate even the slightest imperfection.

Many of the epoch-making products that have forever changed our lives have been made possible with Fujimi's abrasive technologies. Fujimi will continue to strive to produce new abrasive and surface processing technologies that enable our customers to offer new and innovative products.

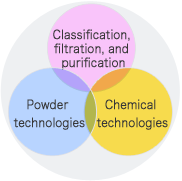

Three core technologies to achieve the ultimate surface

Offering solutions based on our three core technologies: 1) classification, filtration, and purification, 2) powders, and 3) chemicals.

Classification, filtration, and purification

Eliminating impurity and standardizing particle size.

Particles can be separated into varying size using the difference in sedimentary velocity of a liquid (classification). Combining this with a filter to capture particles that are larger than a certain size (filtration), and using ion exchange to produce a highly pure product (purification) are Fujimi's core technologies.

Powder technologies

Improving polishhing efficiency through the power of the particles.

Technologies for designing, producing, selecting, and evaluating particles with a particular function that are appropriate for a particular use.

Chemical technologies

Improving polishhing efficiency and precision through the power of chemicals.

Technologies to design and select chemicals with certain functions such as dispersion and dissolution as well as surface protection.

Fujimi is focused on finding new use for abrasives applying the three core technologies we have developed since our founding.

Meeting the needs of our customers

Fujimi's core technologies can be used in a variety of areas. There are even applications for a number of industries that we never imagined. The FO abrasive that came to be synonymous with Fujimi was originally developed for optical lenses, but a casual inquiry led to the realization that the material could also be used for semiconductors. At that time, we were not even aware of the many applications of semiconductors. The result of that casual question, however, enabled us to make a significant contribution to the development of a more advanced society.

Casual questions and inquiries can be filled with enormous potential. We always try to bear this in mind and respond to even simple questions in a thoughtful and serious manner. Achieving the very best in surface processing cannot be accomplished by relying solely on materials. Fujimi is dedicated to solving problems together with its customers by applying the know-how it has accumulated over many years.

We urge you to feel free to ask questions and to share your challenges with us.

Product search

When product name is known Product line-up