Cemented Carbide Powder for Additive Manufacturing

What is Cemented Carbide?

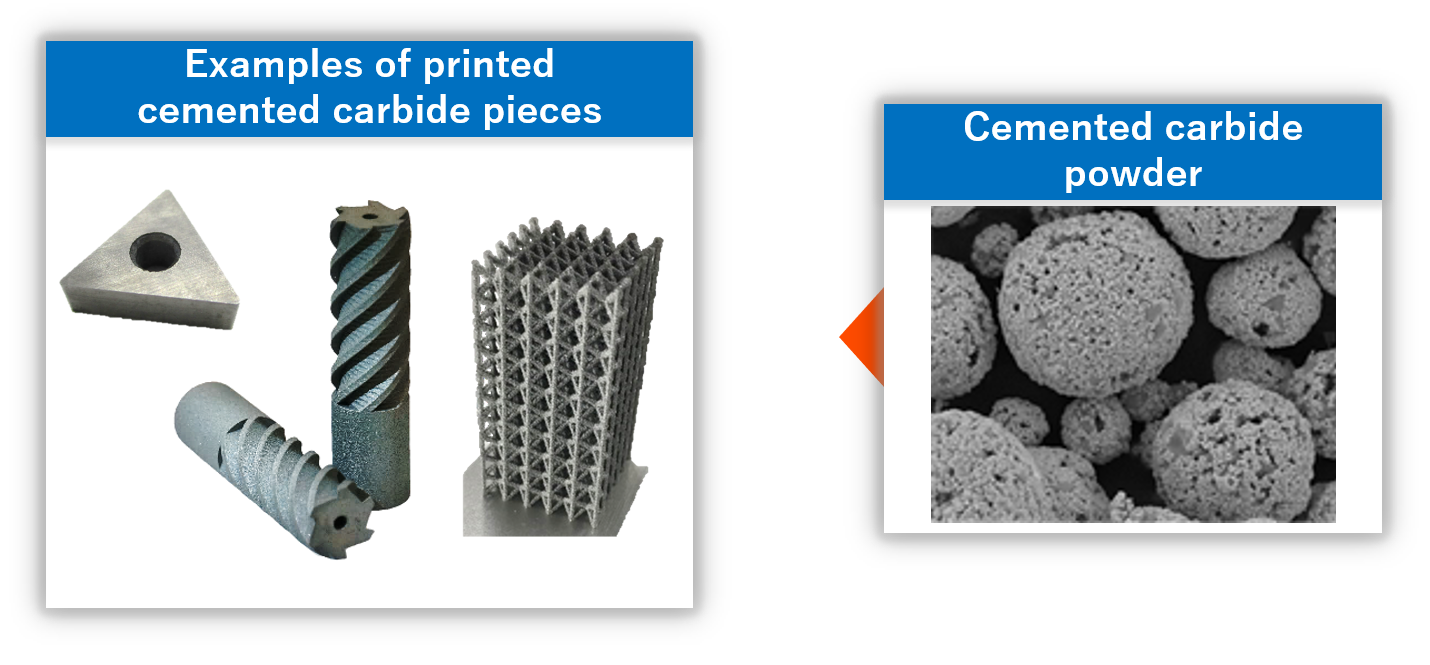

Tungsten carbide based cemented carbide, which features excellent hardness and wear resistance, is widely used for cutting tools, knives, molds and jigs. Manufacturing something like a hollow structure with cemented carbide, machining is required after forming the sintered body. Cemented carbide is very hard and difficult to process complex shapes.

- 1.Design constraints

Difficulties in setting up cooling channels and inline measurement mechanism inside cemented carbide structures. - 2.Long production lead time

In general, it takes several weeks to manufacture a new design of cemented carbide. - 3.Lots of material waste

Cutting processes tend to waste materials, additive manufacturing can be reduced them.

In recent years, to solve these problems, additive manufacturing methods are developed such as LPBF(Laser Powder Bed Fusion) and DED(Directed Energy Deposition), the application of additive manufacturing is also being considered for the purpose of adding functional designs due to specially shaped or linear surfaces.

Our development and design of cemented carbide powders offer new solutions that expand the flexibility of manufacturing with 3D printing technology and provides superior performance of parts.

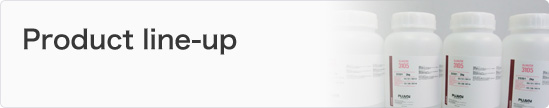

Examples of LPBF Additive Manufacturing

The following photos of additive manufacturing are actual examples molded with 3Dsystems' ProX200.

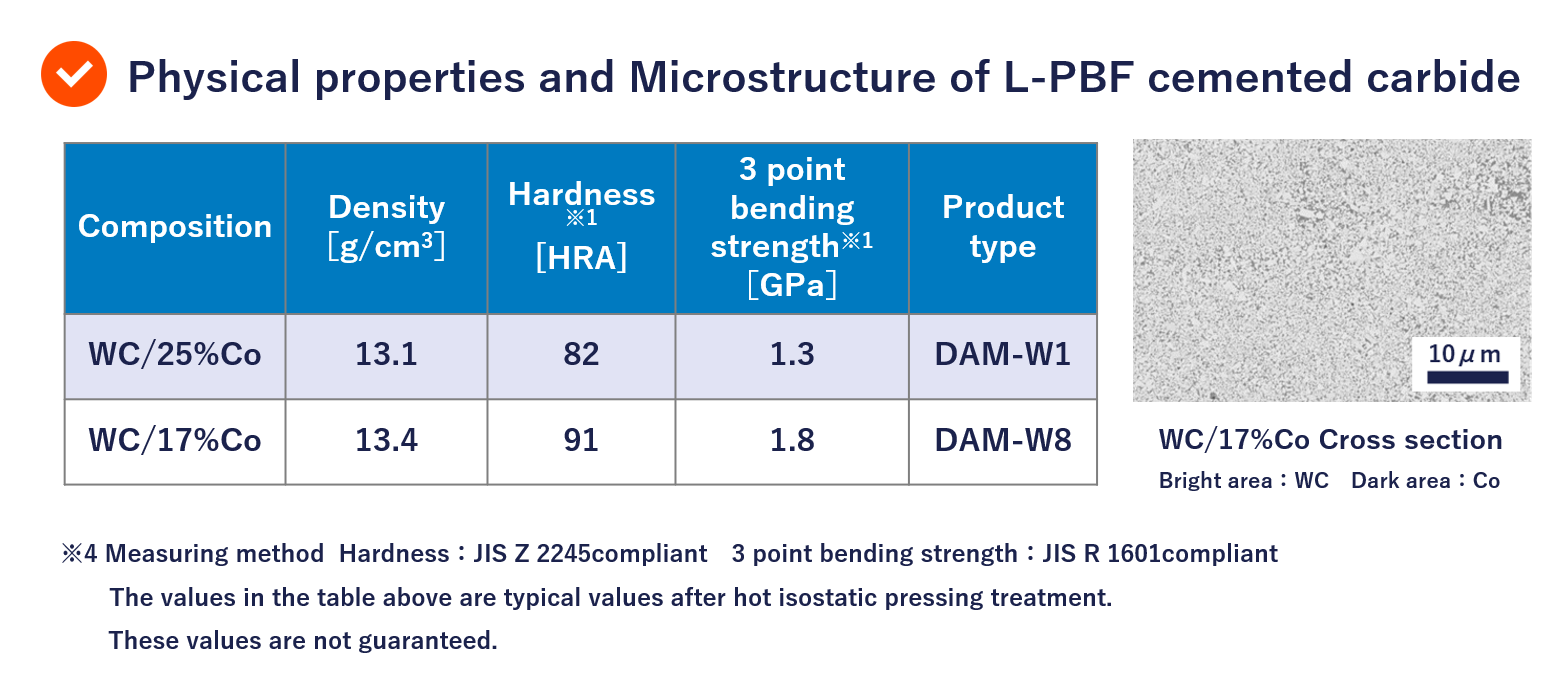

Physical Properties and Microstructure of LPBF Cemented Carbide

The followings are the physical properties and microstructure of LPBF molded with 3D systems’ ProX200

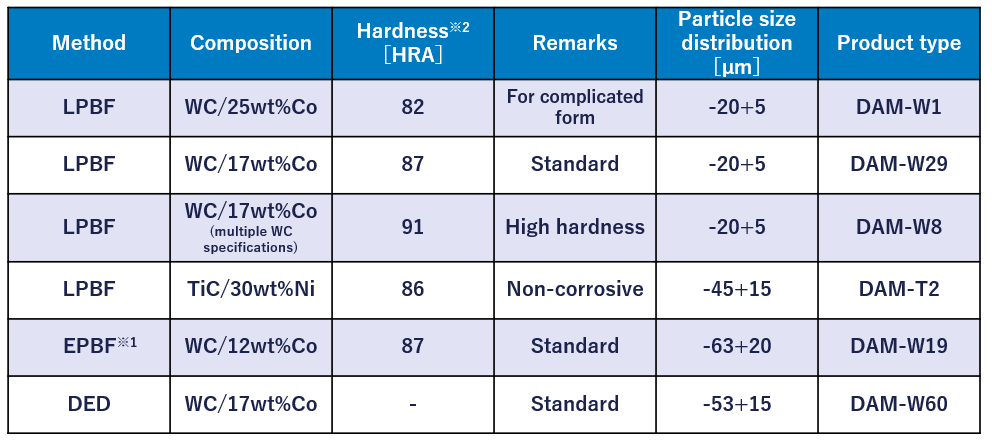

Product Line-up and Features of Our Powder

We offer cemented carbide powders for each processes (LPBF, EPBF*1, DED) of additive manufacturing

*1 Electron Powder Bed Fusion

*2 Measuring method:hardness-JIS Z 2245 compliant

Above table is typical data after hot isostatic pressing treatment.(Not guaranterrd data)

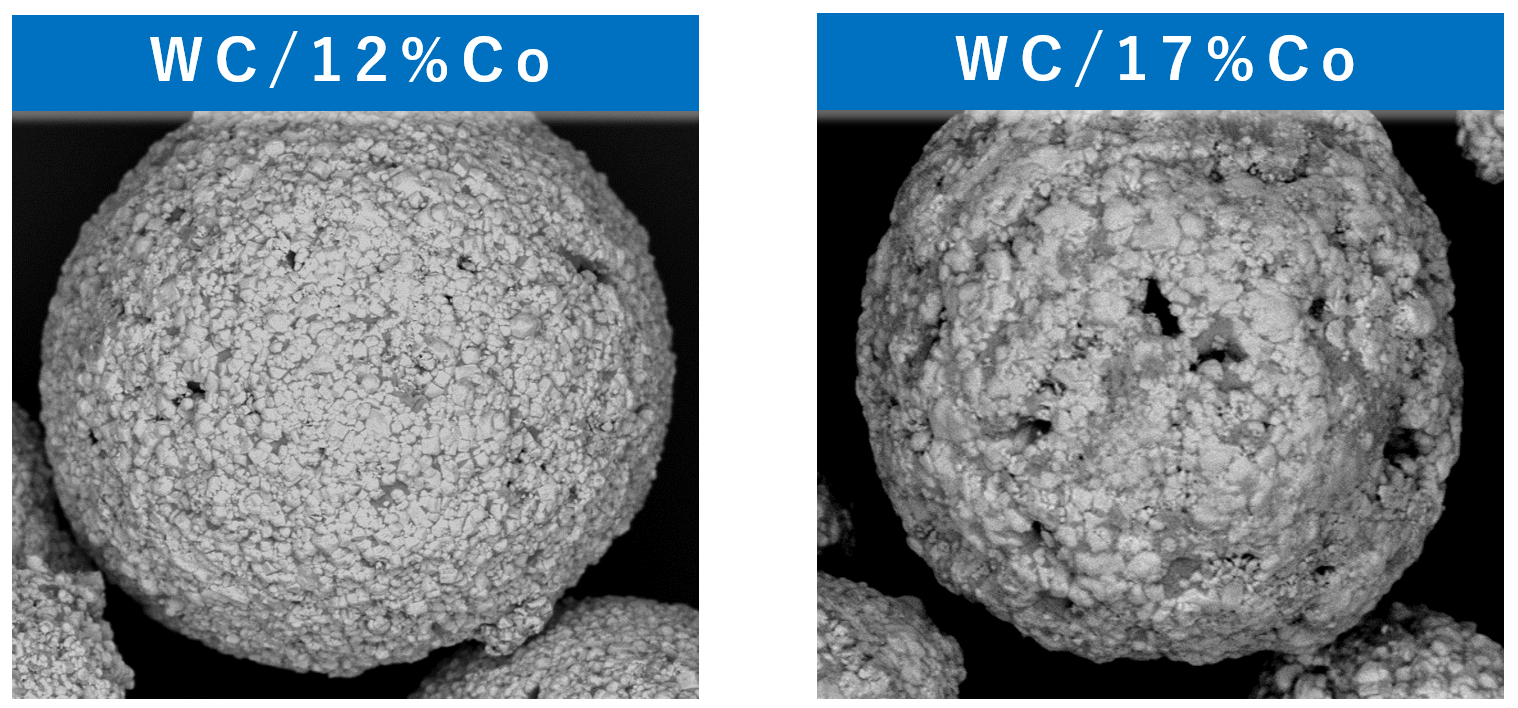

Special features of powder products

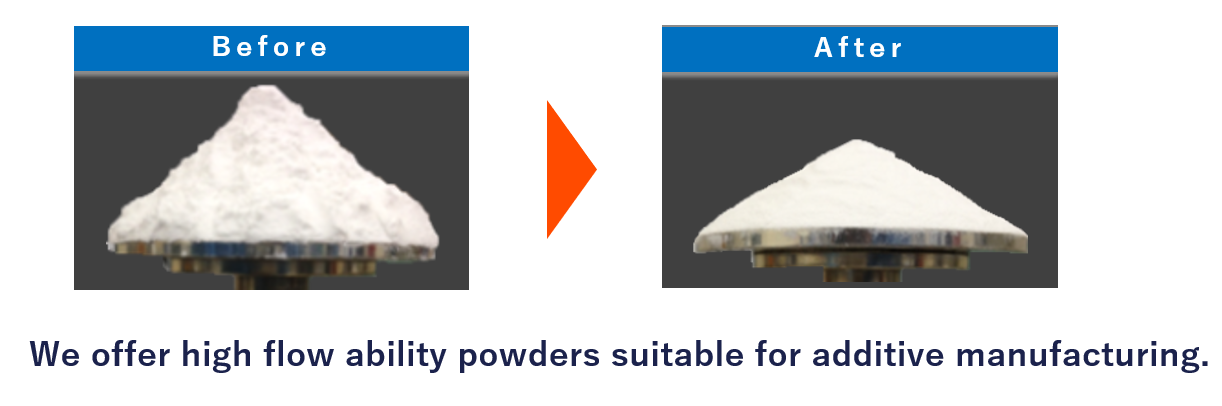

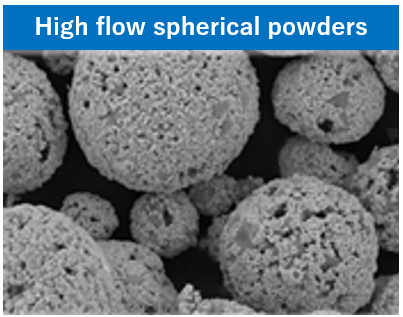

With excellent spheroidal and high fluid powders, we support a stable powder supply and high precision molding.

We offer high flow ability powders suitable for additive manufacturing.

Expected Applications of Cemented Carbide

Our cemented carbide powder is expected to be used in the following applications.

- ・High precision press mold

By producing complicated form which is like holes inside for water cooling, manufacturing time can be reduced significantly. - ・Repair for parts especially for large structure

DED method is effective repair process for application of large structures and lightweight design is expected. - ・Prototype Structure

Enabled cost reductions and shortened delivery time for prototype manufacture with complex structures. - ・Hard coating

High hardness coating is expected to be applied by the DED method.

Fujimi, powder specialist, not only offers high quality materials, but also supports customer’s process by optimize process parameters such as laser powers, scanning speed and laminated thickness for different designs.

If you have any questions about additive manufacturing of cemented carbide powders, please feel free to contact us.