Sintering and Thermal Conductive Filler :

Green Silicon Carbide [GC]

What is Silicon Carbide ( SiC ) ?

Silicon carbide (SiC), is a very hard material—second to diamond in hardness. It is also chemically stable at room temperature. Due to these characteristics, SiC is used as an additive in wear-resistant coatings and plating.

In recent years, heat generation in electronic devices becomes an issue due to the increasing sophistication of communication and mobility, and expectations for thermally conductive materials are increasing, and SiC is used as a thermal conductive filler.

Product Features and Strengths

Our GC series is α-type green silicone carbide. It features the following.

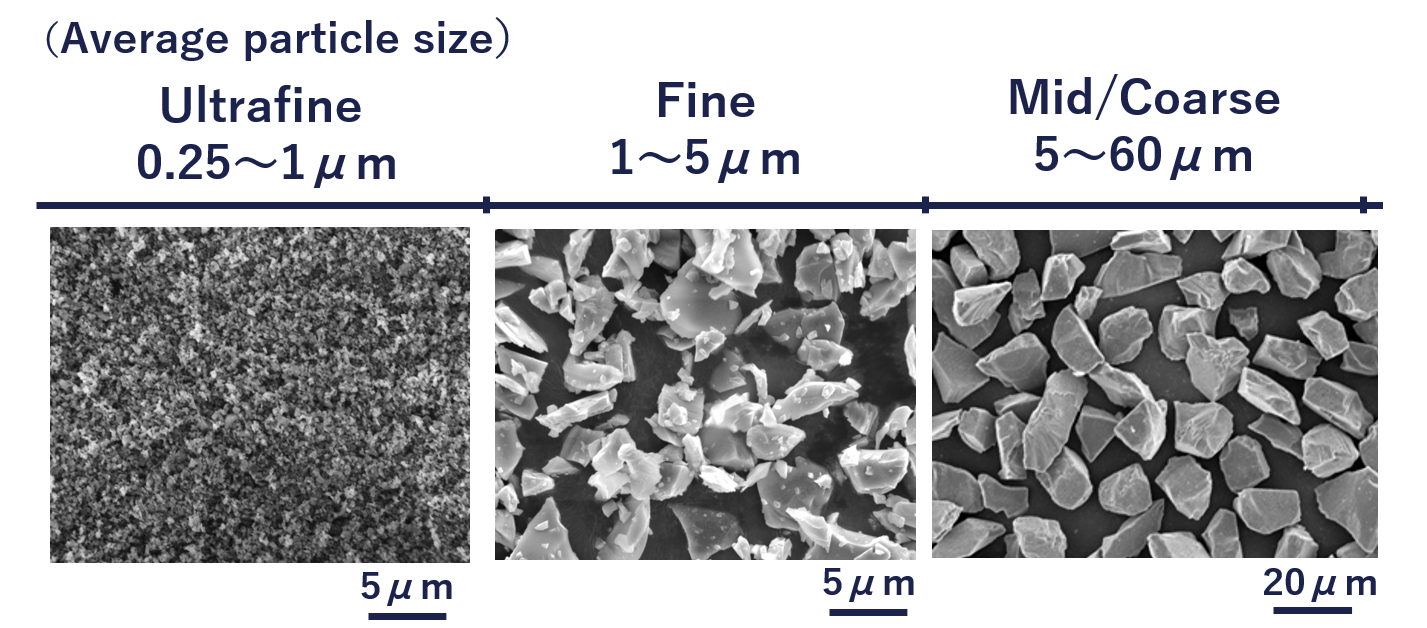

- 1.Line-up: average particle size from ultrafine particle of 250nm to 58µm

- 2.Sharp particle size distribution by our original classification technology

- 3.High purity

Expected Applications for the Product

- ・Raw material for SiC sintered parts (industrial machinery, semiconductor equipment)

- ・Filler (thermal conductivity, heat dissipation, wear resistance, heat resistance)

- ・Grinding wheel

- ・Blasting material

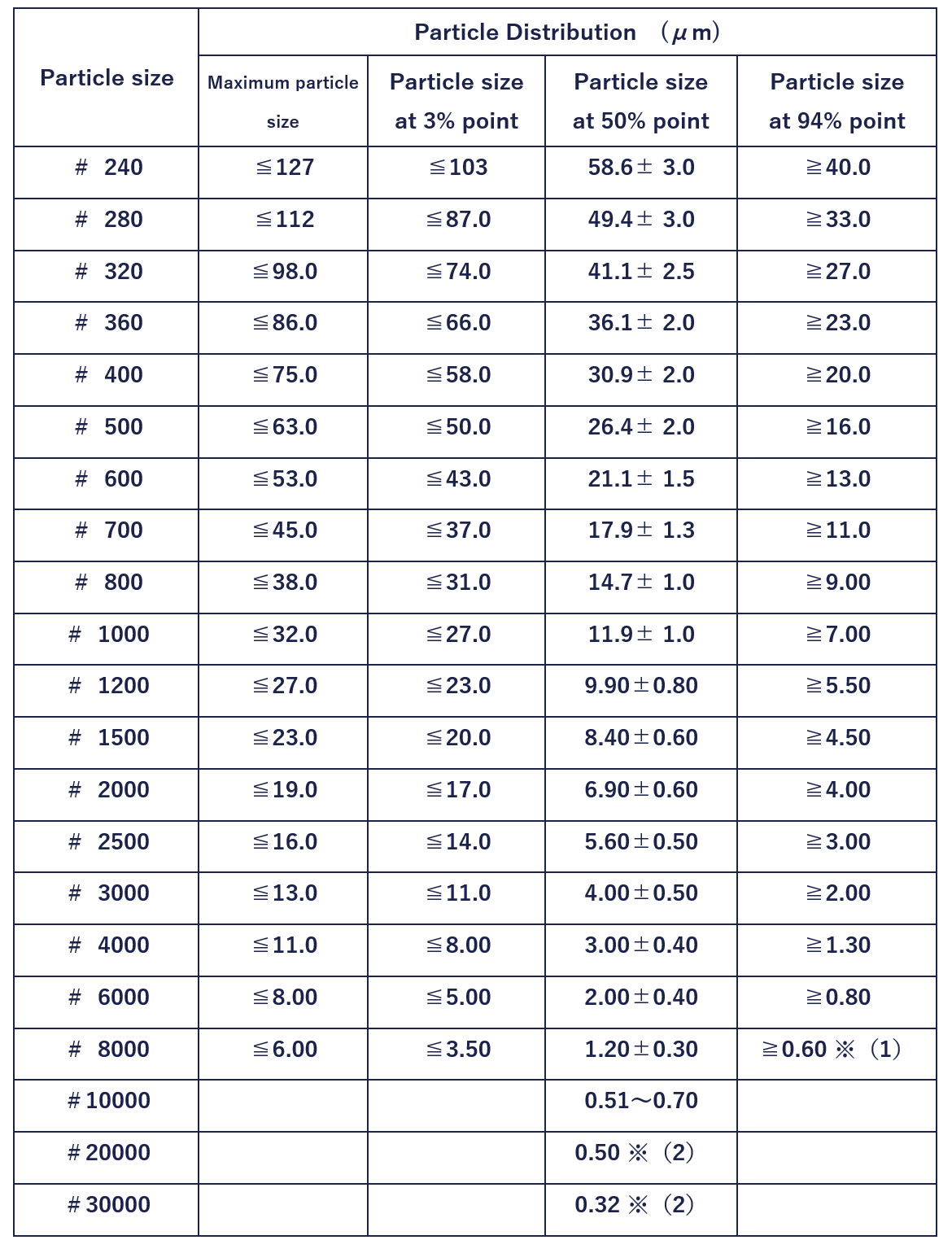

Product Specifications

Particle size is measured by electrical sensing zone methods up to size #8000. by sedimentation balance methods for #10000 and by laser diffraction dispersion methods for #20000, #30000

Note (1): Particle size at 75% point (dv-75 value)

Note (2): Representative value

Examples of Application to Sintered Materials (250nm ultrafine particle, GC#40000)

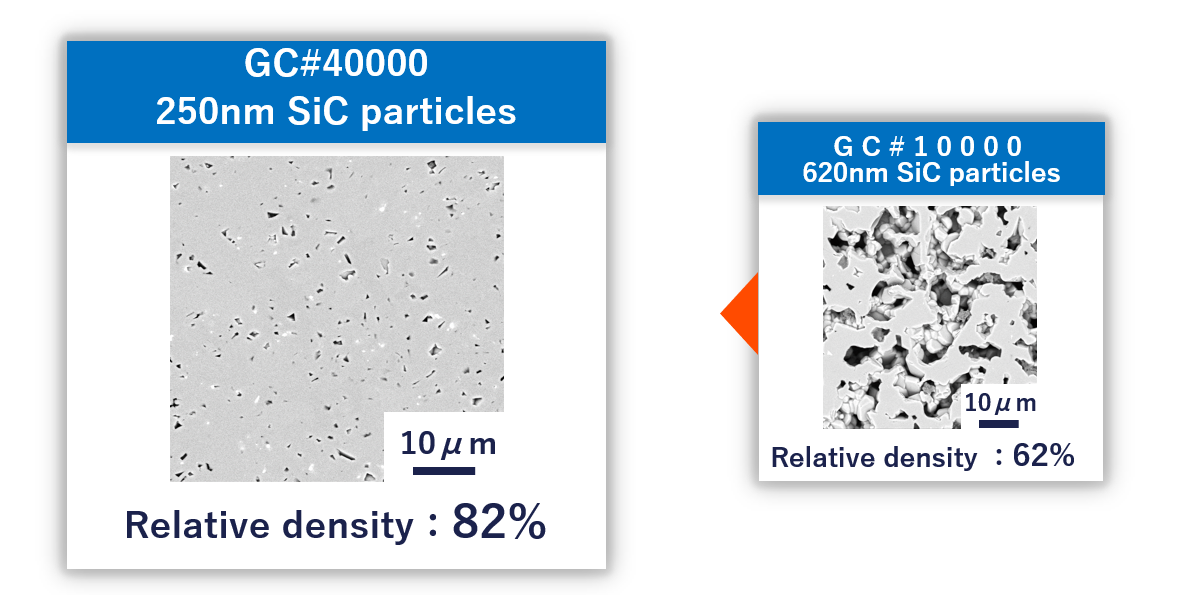

GC#40000 contributes to high density of SiC sintered materials

Silicone Carbide(SiC) Sintered Material Issues

Silicon carbide (SiC) sintered body has excellent chemical resistance, heat resistance, and high thermal conductivity. And they are widely used in semiconductor manufacturing equipment parts. The production of high-density SiC sintered bodies requires a temperature environment of around 2000℃ and more. There is an issue of high load on the equipment.

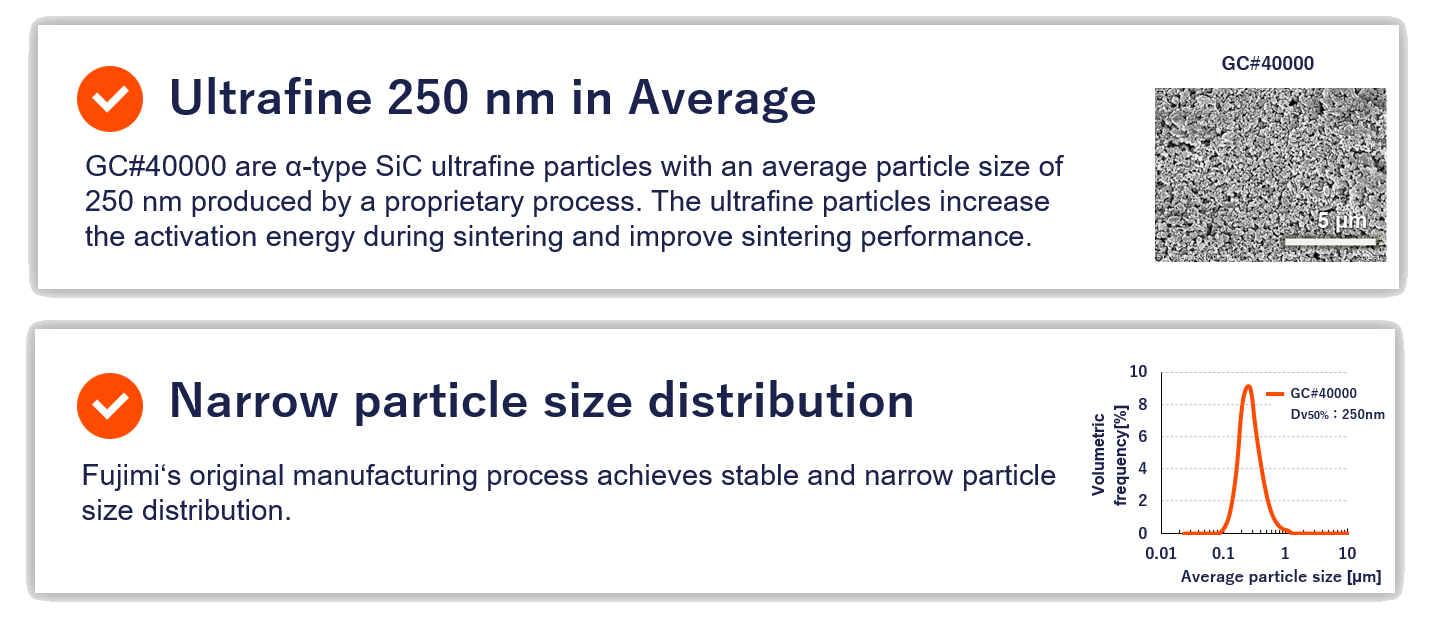

Features of GC#40000

To address these issues, we have developed α-type silicon carbide GC#40000 with nano size. This product has an ultrafine particle of particle size 250nm, which has high active energy. Nano GC#40000 can be sintered at lower temperature than before.

Under the same temperature conditions, higher density and precise sintered body can be achieved.

Features of GC#40000

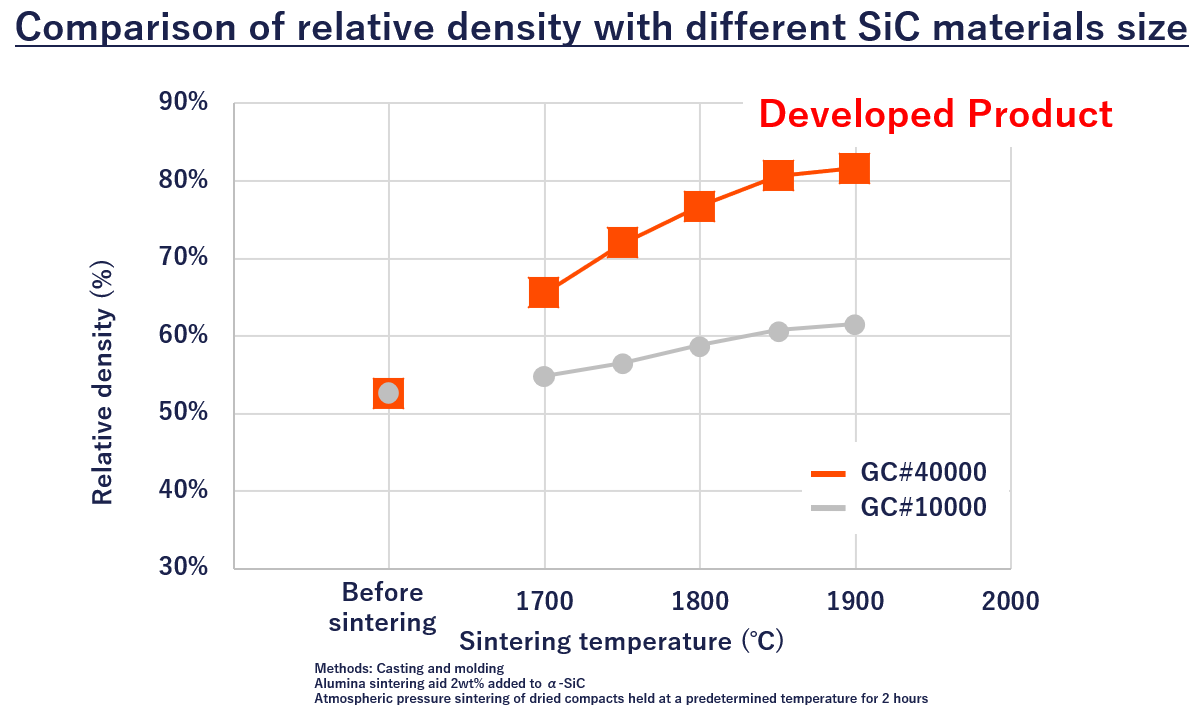

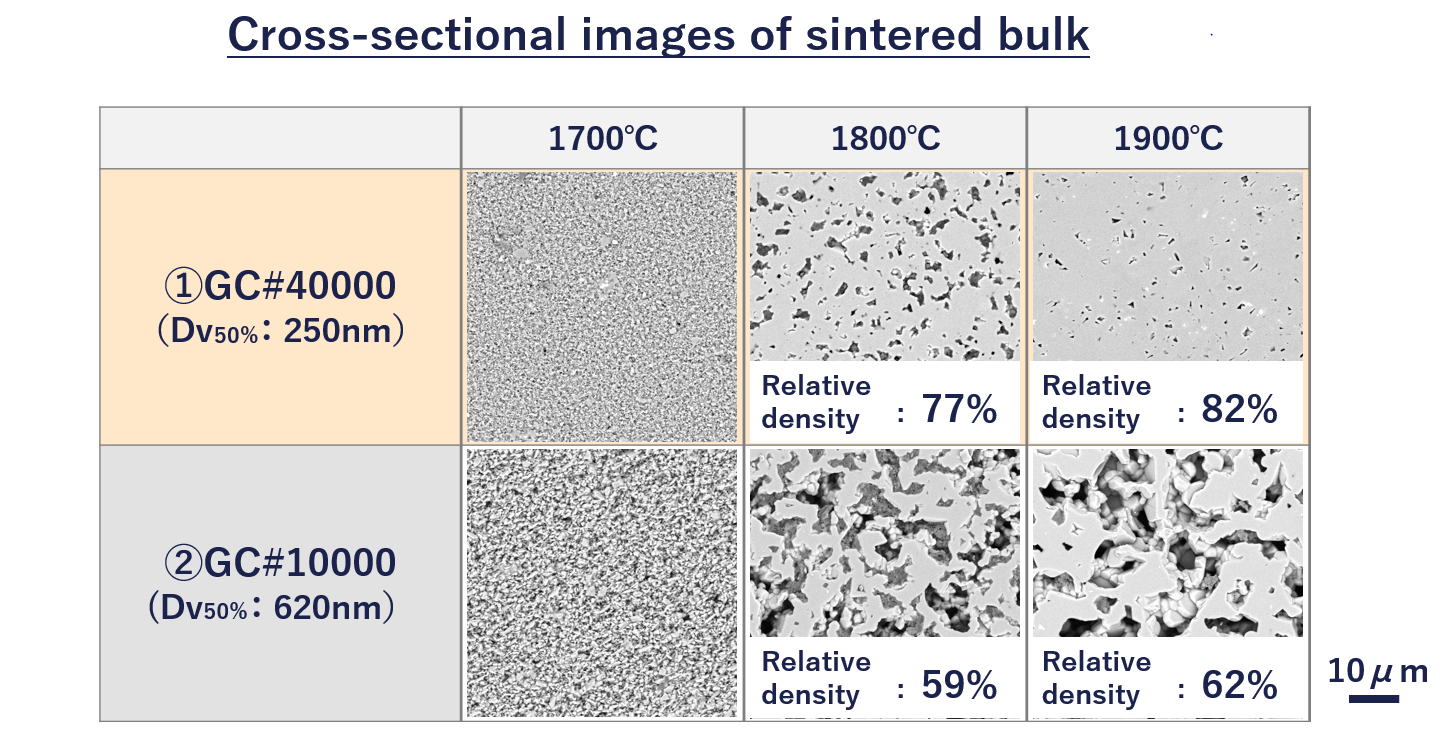

Sintering Performance Evaluation

Ultrafine GC#40000 shows excellent sinterability. Compared to conventional SiC, it achieves higher relative density after sintering, enabling low-temperature densification.

If you have any of the following issues, please feel free to contact us.