Rod-shaped Zinc Oxide

What is the Rod-shaped Zinc Oxide (ZnO)?

Zinc oxide (ZnO) is non-ferrous metal oxide prepared by acid treatment for zinc and is white in color.

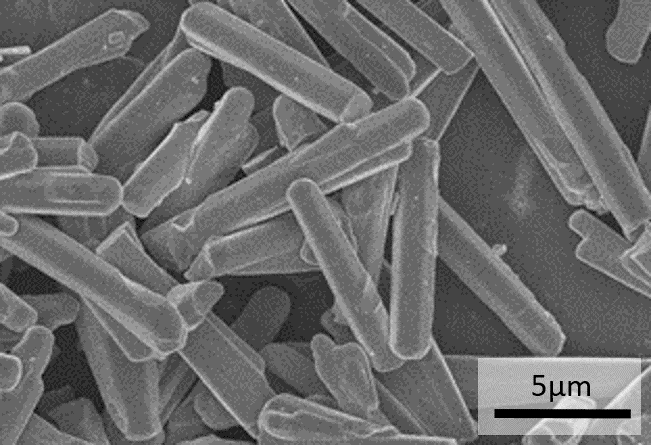

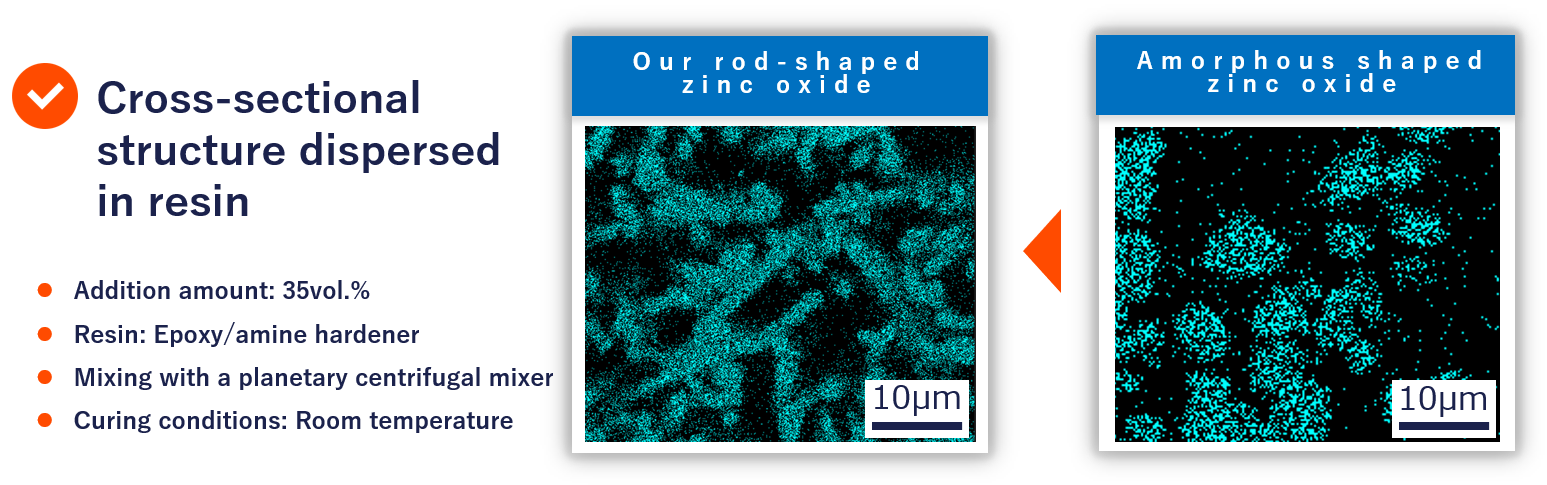

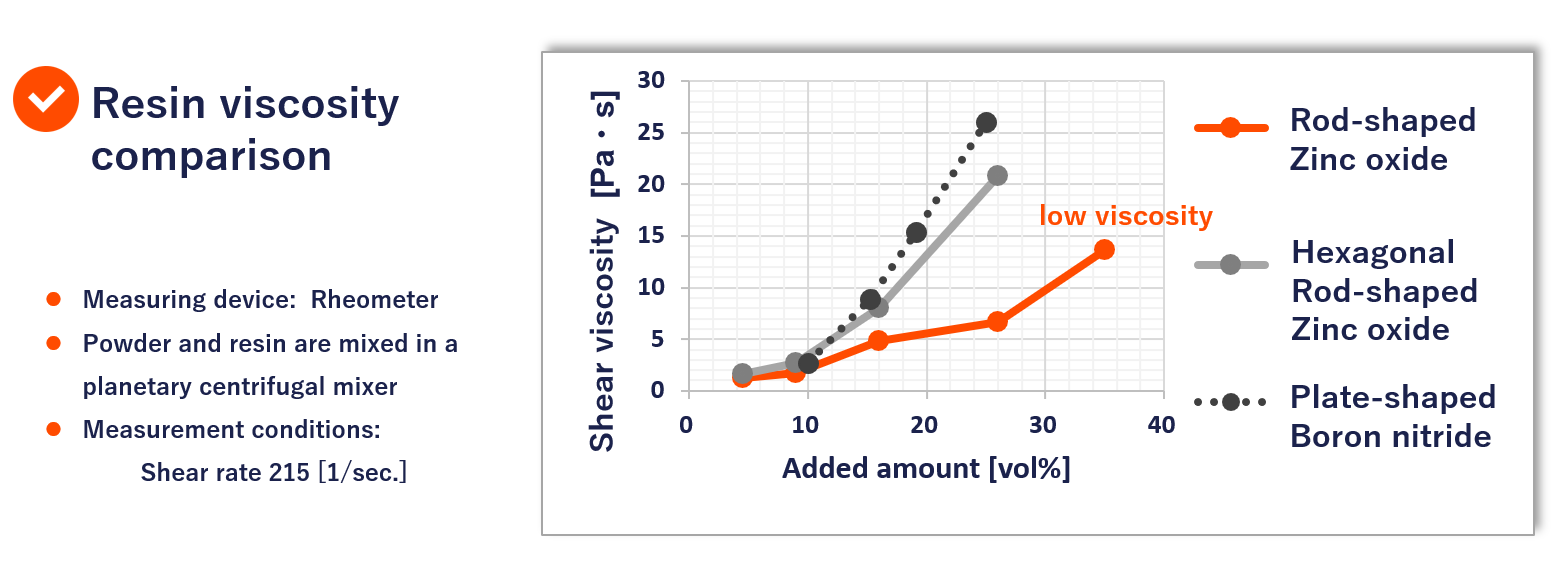

Our zinc oxide is characterized by its rod-like round shape, and it makes easy to fill resins with higher ratio and low viscosity due to smooth rounded shape.

We offer two types of rod-shaped zinc oxide.

1.Rod-shaped zinc oxide for thermal conductivity control.

2.Rod-shaped zinc oxide for electrical conductivity control.

Rod-shaped zinc oxide

Features of Thermal Conductive Filler Rod-shaped Zinc Oxide

In general, zinc oxide as a heat-dissipating material has the following superior characteristics to alumina (aluminum oxide) and magnesia (magnesium oxide).

- 1.Low Mohs hardness and thermal low aggression to equipment for producing heat dissipating components.

- 2.Low coefficient of thermal expansion which minimizes the effect of size changes in heat dissipating components.

- 3.Superior water resistance compared to magnesia.

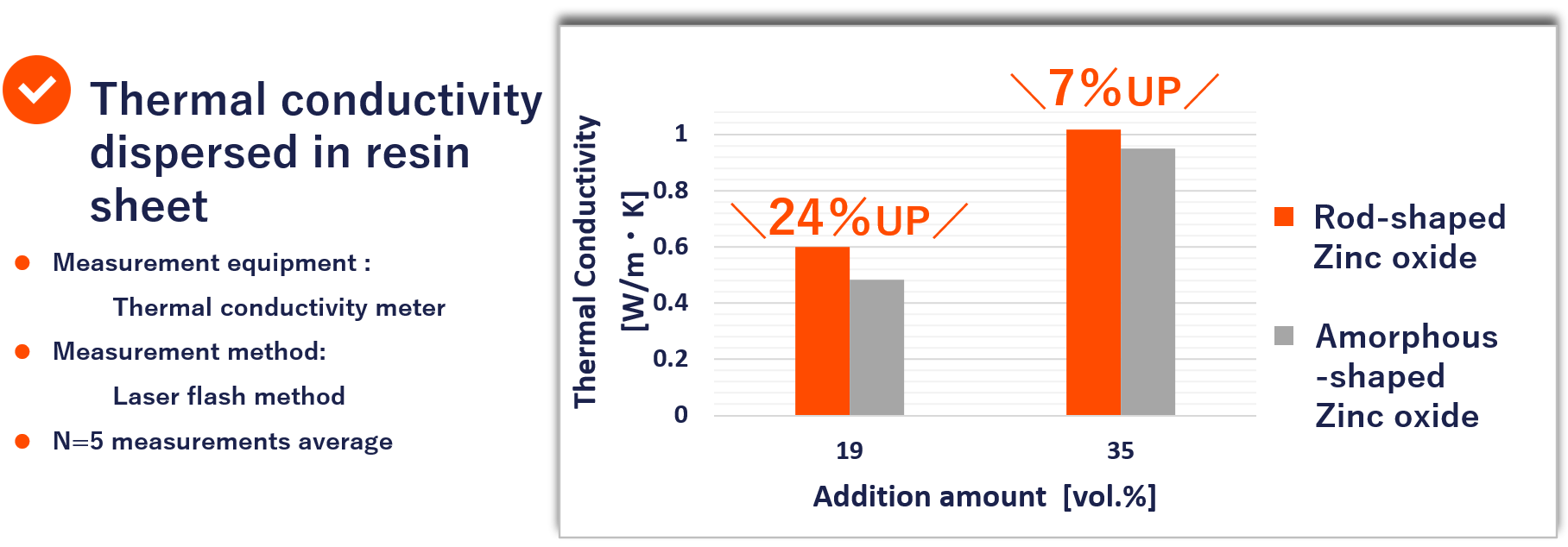

Our thermal conductive filler rod-shaped zinc oxide can be expected to have the following effects on heat dissipating components.

- 1.The high aspect ratio makes it easy to create thermal conductive paths.

- 2.It makes easy to fill resins with higher ratio and low viscosity due to smooth rounded shape.

- 3.It helps to increase contact points between fillers than only with spherical particles.

Rod-shaped zinc oxide increases contact points between fillers, forming thermal conductive pathways.

It makes easy to fill resins with higher ratio and low viscosity due to smooth rounded shape.

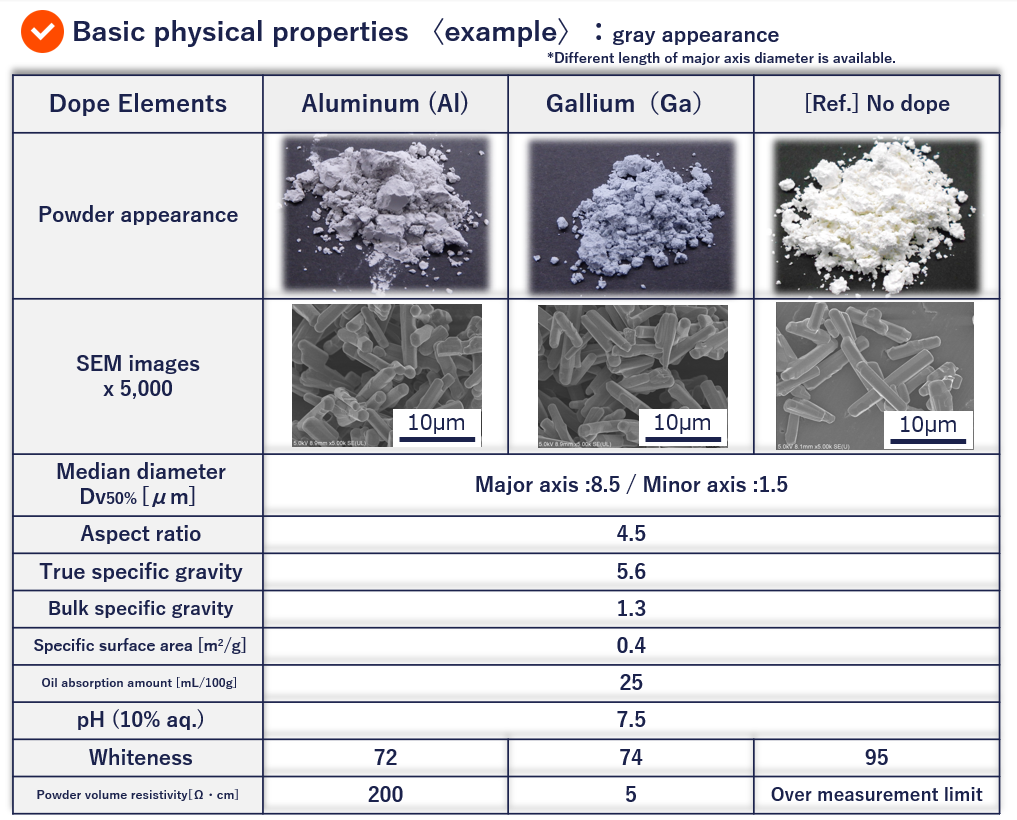

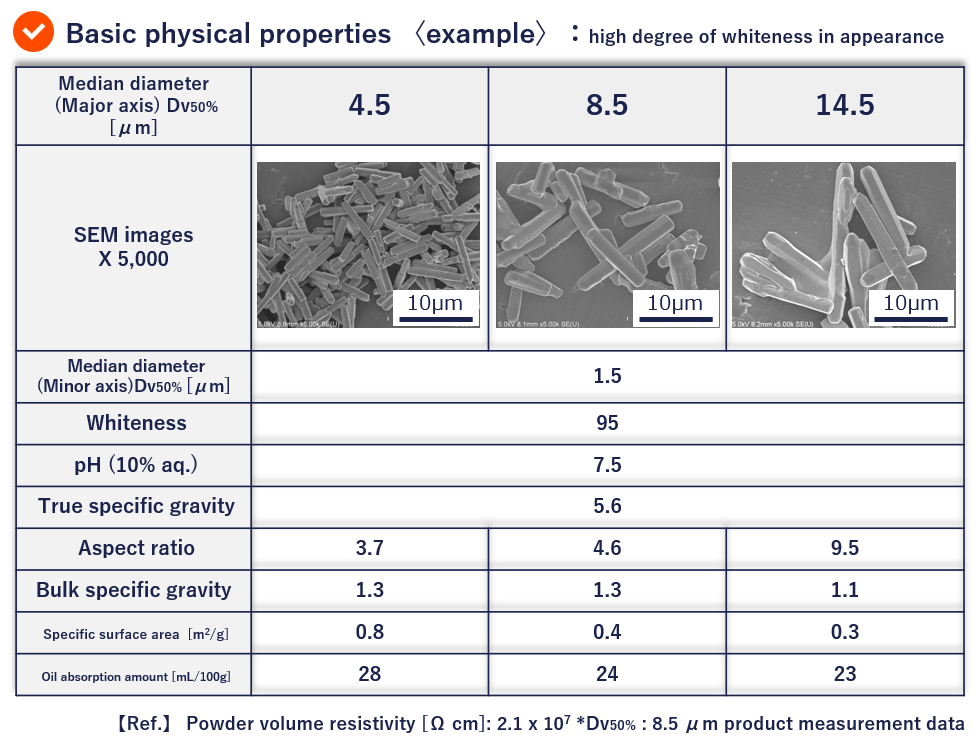

Examples of Physical Properties of Thermal Conductive Filler Rod-shaped Zinc Oxide

If you have any of the following issues, please feel free to contact us.

- ・Want to try thermal conductive filler with characteristic shape.

- ・Facing difficulties in filling boron nitride fillers.

- ・Facing poor water resistance issue with Aluminum nitride filler.

Electrically Conductive Filler Rod-shaped Zinc Oxide

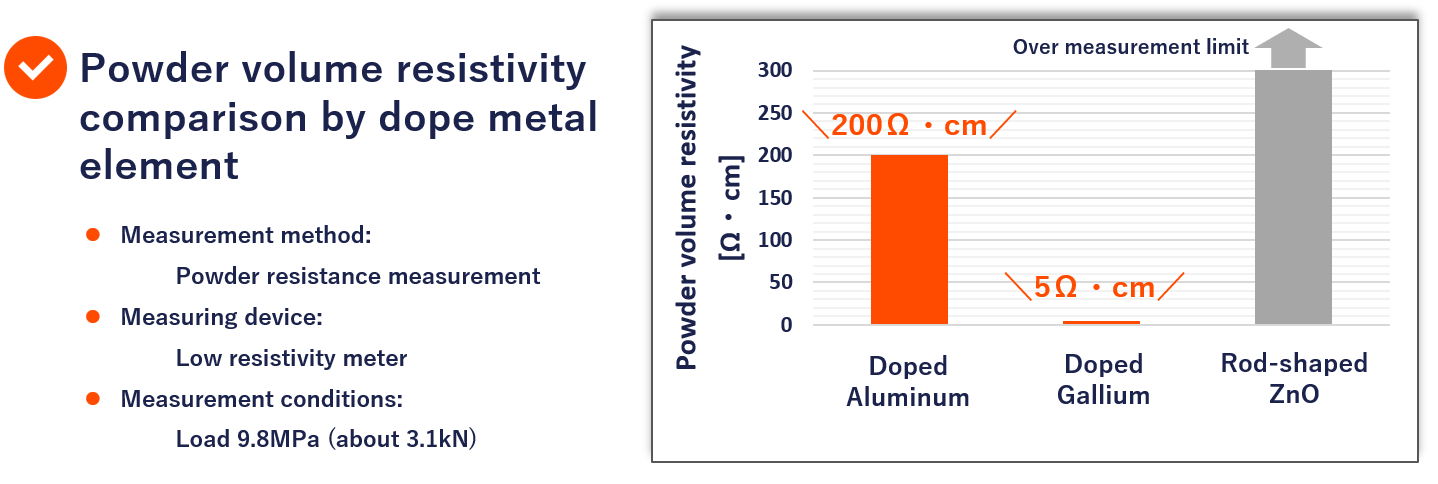

In general, doping aluminum (AZO) into zinc oxide lowers the volume resistivity of the powder to about 200 Ω-cm and is widely used as an antistatic filler.

- 1.Lower Mohs hardness than tin oxide and less aggressive to equipment.

- 2.Sb (antimony) free, making it friendly to both human health and the environment.

- 3.Low whiteness (gray color) makes it easy to maintain dark color design

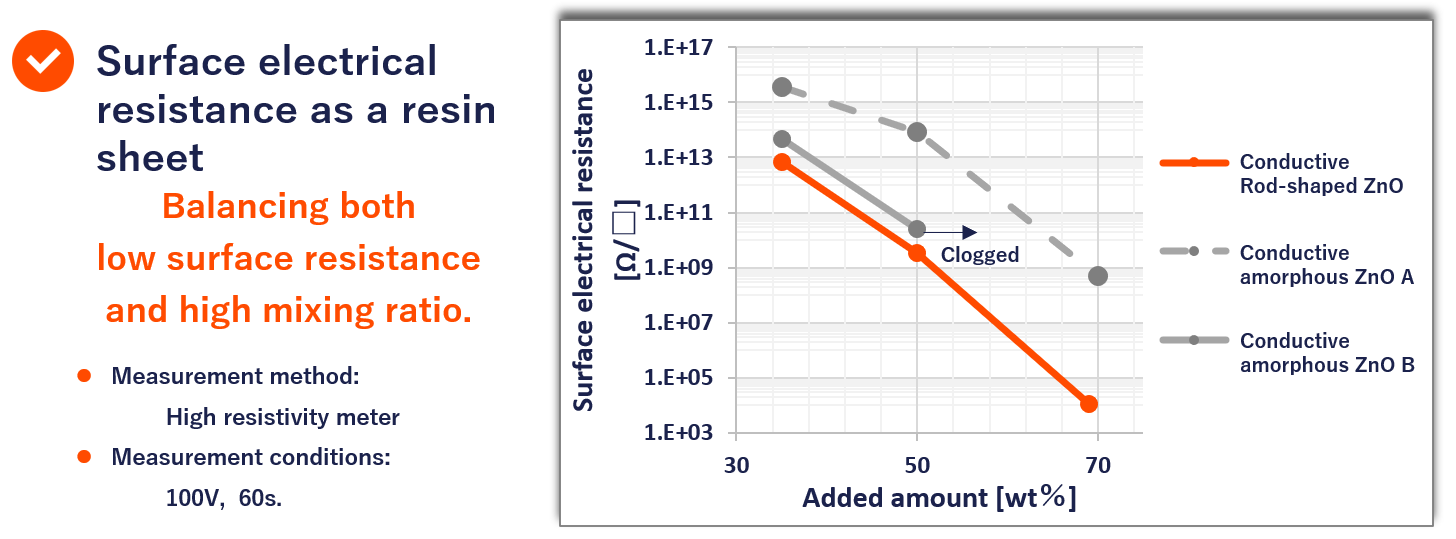

- 1.The high aspect ratio makes it easy to create electric conductive pathways.

- 2.It makes easy to fill resins with higher ratio and low viscosity due to smooth rounded shape.

- 3.Due to changes in dope element species, powders can be selected according to the required electrical conductivity.

Our rod-shaped zinc oxide enables to give electrical conductivity by doping metal elements.

By changing the doped metal element, the conductivity of the material can be adjusted.

Examples of Physical Properties of Electrically Conductive Filler Rod-shaped Zinc Oxide